Helm Instrument Co., Inc.

Helm Instrument Co., Inc.Request A Quote

Maumee, OH | 419-893-4356https://www.helminstrument.com/

At Helm Instrument Co., Inc., we are dedicated to delivering precision solutions for force and torque measurement, helping manufacturers around the world maintain quality and productivity on the shop floor. As a leader in the design and production of industrial-grade load cells and torque transducers, we specialize in creating systems that offer real-time monitoring and control across a wide range of metal forming and assembly applications. We manufacture a comprehensive line of load cells that are engineered to withstand the harsh environments found in stamping, forging, and press operations, and we tailor each sensor to meet the specific dimensional and performance needs of our customers. Our expertise extends beyond hardware. We integrate our sensors with advanced instrumentation and process control software to create full turnkey systems that monitor press tonnage, detect die protection issues, and ensure tooling is performing within specification. With in-house design, machining, and calibration capabilities, we support every stage of the process—from concept through installation and long-term service. Whether our clients require a custom load cell for a new installation or retrofitting a legacy system with digital monitoring, we provide the technical support and engineering know-how to get the job done right. We take pride in being both a manufacturer and a technology partner, empowering our clients to maximize uptime, reduce scrap, and improve part quality through smarter measurement.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

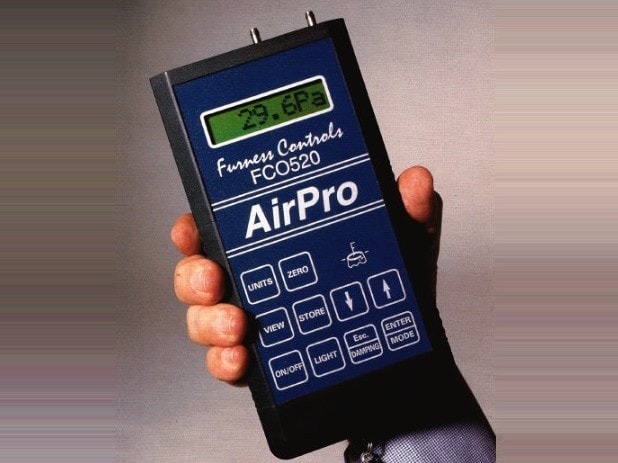

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

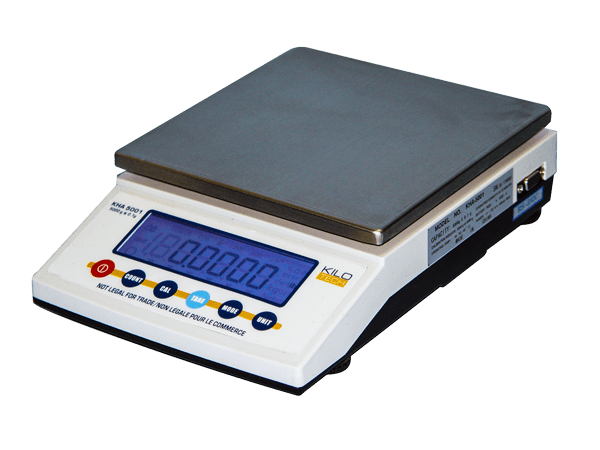

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services