A force sensor is a transducer used to convert an input mechanical stress or force into an electrical signal. Force transducer is another name for force sensors. Force sensors transform the mechanical load applied as an input into output signals whose value can be utilized to estimate the force’s size. The signals may be delivered to indicators, computers, or controllers to act as inputs for controlling machinery and processes or to notify operators. Read More…..

Our load cells are manufactured with the highest attention to detail at all stages. Whether it is through the design stage, engineering stage, or through hundreds of tests run daily, we ensure that our products outshine all competitor products.

Founded in 1985, Load Cell Central has firmly established its reputation as a leader in load cell manufacturing, custom weighing system integration, and first-class load cell repairs. Load Cell Central offers a wide variety of popular load cell and component configurations for virtually every new or old weighing system, scale or component replacement possibility. Technical and after-sale support, ...

At TyTek Industries we manufacture load cells to suit all capabilities. Our expertise has provided insight and load cell solutions for a range of customers and industries. Our engineering team’s philosophy ensures we do everything humanly and technologically possible to match your requirements with quality, cost and delivery. We’re here to help you carry the load.

SENTRAN's corporate charter is to manufacture and market premium quality load cells. SENTRAN serves the biomedical, pharmaceutical, food and beverage, material handling, aerospace, automotive, agricultural, fitness and health, petrochemical and off-shore industries. SENTRAN’s experienced and knowledgeable workforce is capable and ready to find the solution that’s right for you. Call now!

Since 1976, Toledo Integrated Systems has developed force measurement, tonnage monitoring and press control systems for some of the finest manufacturers in the world. We have created many of the innovations that have set the standard for force measurement today. Products include: strain gage sensors and load cells, we’ve also expanded to tonnage monitors, load modules, die protection.

More Force Sensor Manufacturers

Although force sensors and transducers are technically distinct, the two phrases are most frequently used interchangeably. Force sensors come in various sizes and can measure forces ranging from a few hundred grams to hundreds of tons.

Types of Force Sensors

Capacitive Sensors

The analog capacitive sensor performs the same basic duties as regular capacitive sensors, but depending on its use, it has several benefits. There are several advantages when comparing analog capacitive and conventional capacitive proximity sensors. First, they perform well in various contexts, including proximity sensing, concentration variation, product thickness monitoring, and material selection.

Inductive Force Sensors

The position of conductive objects is measured using an inductive sensor. Due to an inductive force sensor’s overall robustness and ability to deliver steady signals even in hostile situations, they are typically utilized in severe environments. In addition, they operate on a contactless principle, which extends their lifespan and increases their dependability.

Inductive sensors are suited to pulling and pushing applications and high dynamic positioning activities within several sectors and situations. They are frequently used in applications involving safety or in situations where great reliability is crucial. Their ideal settings frequently include moisture, water, condensation, high temperatures, and foreign material like dirt, grease, sand, or grit.

Piezoelectric Force Sensors

The quartz crystals in this sensor produce an electric charge proportionate to the applied force when force is applied. This output is gathered on the electrodes positioned in the gap between the crystals and is either sent directly to a charge amplifier outside the sensor or changed into a low-impedance voltage signal there.

For dynamic force applications, piezoelectric force sensors are advised. They are not utilized in static applications as load cells. Sensors with specialized capabilities may be necessary to measure dynamic oscillating forces and impactor high-speed compression/tension under various circumstances. PCB quartz force sensors are known for their quick response times, dependability, stiffness comparable to solid steel, wide dynamic ranges, and capability to measure quasi-static forces.

Piezoresistive Force Sensors

Force sensors that use piezoresistive strain gauges are among the most popular. They employ a material's altered electrical resistance when stretched to gauge force. These sensors' simplicity and robustness make them suited for various applications. The fundamental idea behind a piezoresistive force sensor is to employ a strain gauge made of conductive material that changes its electrical resistance when stretched. A diaphragm that detects a change in resistance when the sensor element is bent can be used to attach the strain gauge. An output signal is produced by converting the variation in resistance.

A conductor's resistance might fluctuate as a result of three different factors. Stretching increases resistance since a conductor's resistance is proportionate to its length. The conductor's cross-sectional area decreases as it is stretched, increasing resistance simultaneously. Lastly, stretching some materials causes their inherent resistance to rising.

Applications of Force Sensors

- Onboard weighing is the process of weighing a heavy commercial or industrial truck's cargo while still within the vehicle. Because of this, vehicles are constantly carrying the maximum amount of weight—neither too little, which would be unsafe nor too much, which would be inefficient.

- A force sensor may be integrated into the scales to weigh the items scanned at the grocery store's self-service checkout.

- Force sensors are used in a variety of ways in the raillway industry. The weights of the passengers, the cargo, or the tractive forces on the drawbar are calculated. All information acquired will be made available to ensure a secure and safe operation inside the prescribed bounds. Along with being used on the railway, force sensors are also used in the track system area.

- Force sensors are used to test objects to determine how much force is applied to them—for instance, the impact of an accident on a motorcycle helmet.

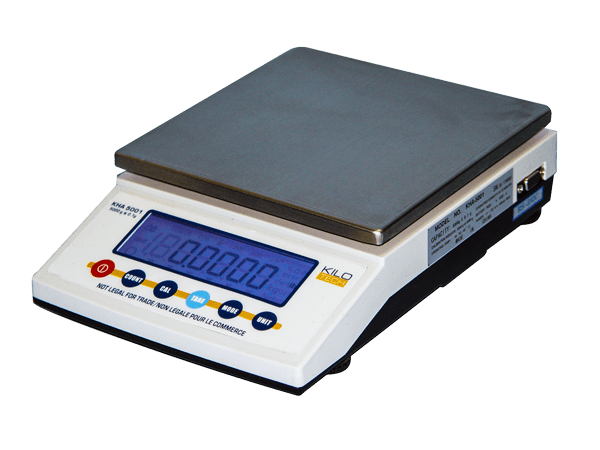

- One of the most common uses for force sensors is in scales. There are many different scales, including bench scales, hopper scales, platform scales, truck scales, belt scales, and more. Force sensors are utilized to get precise results while weighing various materials.

- Many force sensors are used in automobiles. For instance, the presence of force sensors near trailer couplings enables the determination of static data about dynamic driving behavior on the road and the knowledge of the trailer's weight. As a result, the vehicle's control technology may react more quickly and effectively to help a driver.

Choosing the Correct Force Sensor Supplier

To ensure you have the most productive outcome when purchasing force sensors from a force sensor supplier, it is important to compare several companies using our directory of force sensor suppliers. Each force sensor supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each force sensor business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple force sensor companies with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services